PRODUCTS

APPLICATIONS

Coding applications

Software

- Case coding solutions for big box retail suppliers

INDUSTRIES

ABOUT

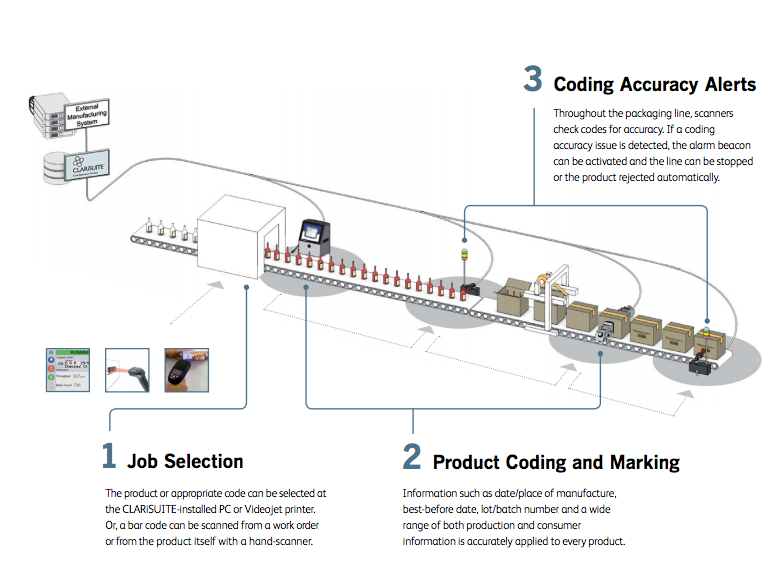

Videojet’s Code Assurance Solution

Videojet’s CLARiSUITE Code Assurance Solutions help ensure that the correct code is applied in the correct location on the correct product and packaging.

How does Code Assurance work?

Featuring centralized message management and printing control, CLARiSUITE is a fully integrated solution linking on-product coding to a centralized message database. Videojet printers in your facility are managed from a central message database — taking message creation and management off the production floor.

What are the customer benefits?

Drive productivity gains in operations by:

Reduce:

Secure and streamline data management by:

Protect the brand by:

Videojet’s expertise reaches beyond printing codes to integrating the systems that secure and streamline the management of message data.

The right solution for your packaging line

From simple date codes to serialized shipping container codes, Videojet’s CLARiSUITE Code Assurance Solutions are powerful, expandable, flexible and compatible with most of Videojet’s printers

Dutch Gold Honey Case Study

“After we implemented CLARiSUITE, it eliminated 99.9% of our coding problems.”

Jim Gerlach, Production Scheduler, Dutch Gold Honey

The Linx 7900 is a robust printer suitable for coding onto products in a wide range of industries. A range of automated features increase productivity and reduce code errors – improving your efficiency and lowering total cost of ownership.

Prints up to 5 lines of code on line speeds up to 8.41m/s (for single line of code)

Purpose designed for reliable ink jet coding onto bottles. Unique air knife and printhead system ensures the bottle is dried prior to printing, for good ink adhesion. Prints up to 5 lines of code.

Electronic marking solution prints micro characters from 1.1mm high, plus ‘tower’ printing, with a specialist ink free from chromium and halogens. Prints up to 4 lines of code.

Purpose-designed for reliable printing with dedicated specialist food grade inks to meet FDA and EU regulations. Prints up to 5 lines of code.

Reduced solvent consumption of up to 40%, whilst still delivering maximum reliability. Prints up to 5 lines of code.

Narrow font for printing into small areas such as bottle tops, and on line speeds up to 6.83m/s (for single line of code). Prints up 2 lines of code.