PRODUCTS

APPLICATIONS

Coding applications

Software

- Case coding solutions for big box retail suppliers

INDUSTRIES

ABOUT

Readable and accurate codes on cases and cartons are critical for effective inventory and supply chain management. The range of Videojet coding solutions includes high and low-resolution ink-based systems and automatic label printers and applicators.

Supplying products in cases/trays to a big box retailer like Walmart®? Learn how Videojet case coding solutions can help you meet requirements.

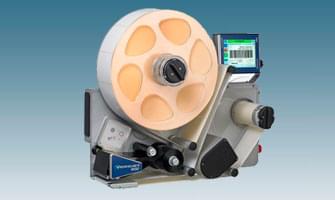

When labels are required instead of direct box printing, you can automatically print and apply labels to cases and cardboard boxes with Direct Apply™ accuracy. Optional application methods include telescopic tamp, front-of-pack, and rear corner wrap.

Automatic label applicators provide precise placement of pre-printed labels and eliminate the need for manual or hand-apply processes. Labels can be applied to corrugate boxes, cartons, shrink wrap, pallets, and clamshells.

The Videojet 2300 line of case coders meets the need for scannable barcodes and crisp high-resolution text. Print alphanumeric text, logos, images, and bar codes on demand on corrugate cases, boxes, shipping cartons, trays, and building materials.

Print product information, identification numbers, production counts, and accurate-to-the-minute time codes at the touch of a button. Choose from low-resolution options including an economical cost-per-code box printer that delivers one or two lines of text and features built-in language selection.

The Linx 7900 is a robust printer suitable for coding onto products in a wide range of industries. A range of automated features increase productivity and reduce code errors – improving your efficiency and lowering total cost of ownership.

Prints up to 5 lines of code on line speeds up to 8.41m/s (for single line of code)

Purpose designed for reliable ink jet coding onto bottles. Unique air knife and printhead system ensures the bottle is dried prior to printing, for good ink adhesion. Prints up to 5 lines of code.

Electronic marking solution prints micro characters from 1.1mm high, plus ‘tower’ printing, with a specialist ink free from chromium and halogens. Prints up to 4 lines of code.

Purpose-designed for reliable printing with dedicated specialist food grade inks to meet FDA and EU regulations. Prints up to 5 lines of code.

Reduced solvent consumption of up to 40%, whilst still delivering maximum reliability. Prints up to 5 lines of code.

Narrow font for printing into small areas such as bottle tops, and on line speeds up to 6.83m/s (for single line of code). Prints up 2 lines of code.